World’s first*1 IoT-based cooling box that uses contactless power supply technology

Osaka, Japan – Panasonic Corporation today announced to begin offering rental services using VIXELL™, the world’s first*1 Vacuum Insulated cooling box that uses contactless power supply technology to enable the user to determine insulation performance.*2 To start with, Panasonic will collaborate with the Suzuken Group and launch a fulfilment service in Japan. VIXELL™ is ideally suited to the temperature controlled transportation of pharmaceuticals and vaccines, and the fulfilment service will include rentals, a reception service, precooling, delivery,*3 and more. Applications will be accepted from March 2 with a view to rolling out the service from April 2021.

For the insulation layer, the most important part of a cooling box, VIXELL™ utilizes Panasonic’s patented Vacuum Insulated Case (VIC),*4 a seamless, integrally molded body with no joints. The thermally insulated structure prevents cool air from leaking out and can maintain a -75ºC±15ºC environment for up to 18 days.*5 Unlike conventional Vacuum Insulated panels, Panasonic’s VIC is not covered in aluminum film, allowing the transmission of radio waves and magnetic field, and making it easier to connect with IoT devices. The VIC is also preinstalled with a wireless vacuum sensor that uses contactless power supply technology, and so simply by placing the box on the dedicated inspection stand, users can check the vacuum condition inside. This allows users to ascertain the insulation performance*2 of the box prior to transport, providing them with peace of mind. Further, by installing temperature or GPS sensors*6 inside the box, users can monitor the internal condition of the box without having to open it.

The transportation of pharmaceuticals requires strict temperature and tracking management, while the work itself must be efficient. Panasonic began development of cooling boxes for the transportation of pharmaceuticals in 2018. Since then, it has repeatedly visited worksites and listened to first-hand opinions in order to improve the product. Using the thermal insulation, molding, and IoT technologies it has accumulated over many years in the development of refrigerators and other home appliances, Panasonic is aiming to provide enhanced reliability and safety, and create new value in the transportation of pharmaceuticals.

Panasonic will continue to use its strengths in technology to help make healthy living a reality.

Main Features of VIXELL™

1. Use of a unique Vacuum Insulated Case*4 for outstanding thermal insulation and longtime cooling

a) Seamless, integrally-molded body for outstanding thermal insulation and longtime cooling

Conventional insulated boxes are manufactured by joining Vacuum Insulated panels (VIPs) together, but a drawback of this structure has been that cool air leaks through the gaps where the panels join. VIXELL™ utilizes Panasonic’s patented Vacuum Insulated Case (VIC)*4—a seamless, integrally-molded body with no joints—to prevent cool air escaping, and enhance insulation performance. As a result, the box can maintain a temperature of 75ºC±15ºC for up to 18 days.*5

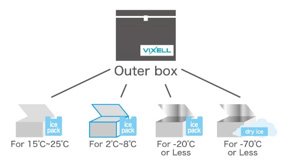

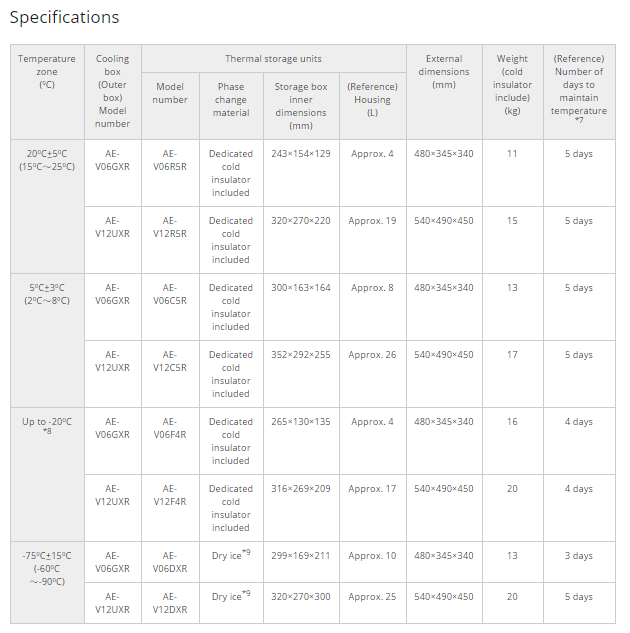

b) Caters to a diverse range of temperature zones through use with thermal storage units

For certain insulation boxes, the outer box has to be changed depending on the designated temperature, but with VIXELL™, the same outer box can be used for all temperatures. By changing out the thermal storage unit—comprising the storage box and the phase change material—VIXELL™ can cater to a wide range of temperature zones (up to -75ºC±15ºC, up to -20ºC, between 2ºC and 8ºC, between 15ºC and 25ºC). Not only does VIXELL™ conserve resources, it also contributes to enhanced work efficiency.

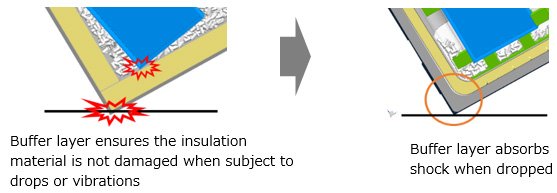

c) Highly durable VICs and shock-absorbing structure to reduce risk of damage when dropped

Unlike VIPs, which are covered in a thin layer of aluminum and plastic film, VICs are covered in a layer of plastic sheet. This gives the VIC outstanding durability and means it is resistant to cracks. Both the inside and outside of the VIC are protected by a buffer layer, helping to reduce the risk of damage when the box is subject to drops or vibrations during transport or work. Even if the dry ice sublimates and reduces in volume, the buffer layer prevents the storage box carrying the contents from bumping into the VIC.

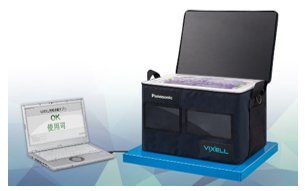

2. World’s first*1 wireless vacuum sensor to use contactless power supply technology

Unlike Vacuum Insulated panels, which are covered in aluminum and plastic film, VIXELL™ VICs are covered in a layer of plastic sheet, allowing the transmission of radio waves and magnetic field. Preinstalled in the VIC is a wireless vacuum sensor that uses contactless power supply technology. By placing the box on a dedicated inspection stand, the sensor unit is supplied with power, allowing the user to easily check the vacuum condition of the VIC. With conventional Vacuum Insulated products, damage during transport and long-term use has led to a deteriorating vacuum effect, and in turn lesser insulation performance. With VIXELL, users can ascertain the insulation performance*2 of the VIC prior to use, giving them peace of mind.

Internal wireless vacuum sensor

Inspection software Inspection stand

3. Wireless connection to IoT devices and monitoring inside the box without opening

VICs can connect with IoT devices as they allow the transmission of radio waves. By installing temperature or GPS sensors inside the box, users can monitor the internal condition of the box without having to open it.

Inspect contents without

opening the box

Product Line-up

Cooling Boxes

Thermal Storage Units

Notes:

- *1: Among vacuum insulation products equipped with a near field communication device. (in-house investigation; current as of March 2, 2021)

- *2: Only the insulation performance of VICs can be determined.

- *3: Delivery of precooled boxes, not those containing pharmaceuticals and vaccines.

- *4: Vacuum Insulated material, with a core material covered in high gas-barrier plastic, in a vacuum state.

- *5: Testing conditions: Dry-ice temperature zone thermal storage unit (AE-V12DXR) inside Type-L Vacuum Insulated cooling box (AE-V12UXR), with a total of 34 kg of dry ice in both. With a mock product inside (dimensions: 231 x 231 x 40 mm), test measured for how many days a temperature of -75ºC±15ºC was maintained with an outside temperature of 30ºC.

Testing conditions: Dry-ice temperature zone thermal storage unit (AE-V06DXR) inside Type-S Vacuum Insulated cooling box (AE-V06GXR), with a total of 14 kg of dry ice in both. With a mock product inside (dimensions: 213 x 115 x 40 mm), a temperature of -70ºC±15ºC was maintained for up to nine days with an outside temperature of 30ºC. - *6: Temperature and GPS sensors are not included with VIXELL.

- *7: In-house result when measuring the temperature inside the storage box. For the 15ºC~25ºC temperature zone, the outside temperature was set at 5ºC, and for other temperature zones, the outside temperature was set at 30ºC. Results will differ depending on the usage environment.

- *8: Product catering to a -20ºC±5ºC temperature zone is currently under development.

- *9: Thermal storage unit for use in the -75ºC±15ºC temperature zone does not come with dry ice.

Website:

Panasonic VIXELL Website

https://www.panasonic.com/global/business/vixell/

Media Contact:

Panasonic Corporation Brand Strategy Division Corporate PR Department

https://news.panasonic.com/global/contacts/

Inquiries:

Business Development Center, Appliances Company, Panasonic Corporation

(Email: vixell_inq@gg.jp.panasonic.com)

About Panasonic

Panasonic Corporation is a worldwide leader in the development of diverse electronics technologies and solutions for customers in the consumer electronics, housing, automotive, and B2B businesses. The company, which celebrated its 100th anniversary in 2018, has expanded globally and now operates 528 subsidiaries and 72 associated companies worldwide, recording consolidated net sales of 7.49 trillion yen for the year ended March 31, 2020. Committed to pursuing new value through innovation across divisional lines, the company uses its technologies to create a better life and a better world for its customers. To learn more about Panasonic: https://www.panasonic.com/global.