Osaka, Japan – Panasonic Corporation announced today that its Industrial Solutions Company has commercialized R-5410, Halogen-free Ultra-low Transmission Loss[1] Multi-layer Circuit Board Material suitable for millimeter-wave[2] antennas. Mass production will begin in March 2021.

– Low Transmission Loss Circuit Board Material is suitable for automotive

millimeter-wave radars and 5G wireless communication base stations

– This material improves antenna performance and reduces circuit board manufacturing costs

Millimeter-wave (mmWave) is a specific type of radar technology that employs short-wavelength electromagnetic waves. Radar systems transmit signals and receive signals reflected by objects in their path. By processing the reflected signal, a radar system can determine the range, velocity and angle of the objects. Millimeter-wave radar[3] is a key technology for automotive, telecommunications and other industries. These systems form the basis for the driving environment recognition platforms which enable advanced driver-assistance systems (ADAS) technology.

With the aim of achieving enhanced Mobile BroadBand (eMBB), massive Machine Type Communications (mMTC), and Ultra-Reliable and Low Latency Communications (URLLC) in 5G (5th generation mobile communication systems), wireless communication base stations also use millimeter-wave bandwidths with beamforming technologies[4] based on massive-element antennas. The rapid adoption of millimeter-wave radar has increased the performance requirements for high-frequency circuit boards used for wireless communications. Demand has increased for multi-layer circuit board materials that exhibit low transmission loss in the millimeter-wave band.

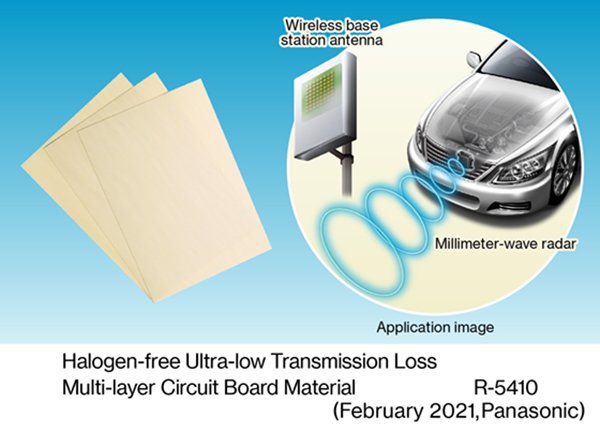

Historically, fluoropolymer circuit board materials[5] have been primarily used for manufacturing antenna circuit boards. However, these fluoropolymer materials are thermoplastic and can be difficult to process into multi-layer constructions. The newly developed R-5410 Halogen-free Ultra-low Transmission Loss Multi-Layer Circuit Board Material is a prepreg material made from a unique non-fluoropolymer thermosetting resin system. This new prepreg enables multi-layer antenna constructions using industry-standard circuit board lamination manufacturing processes[6] and equipment. This feature increases the flexibility of high-frequency circuit board designs, enabling compact and high-density modules integrated with antennas at reduced material and processing costs and improving the efficiency of antenna performance.

Panasonic’s new halogen-free ultra-low transmission loss multi-layer circuit board material has the following features:

1. R-5410 has lower transmission loss which improves the efficiency of millimeter-wave band antenna signals.

- • Transmission loss: 0.079 dB/mm (@79 GHz)

(Panasonic’s conventional product*1: 0.081 dB/mm)

2. R-5410 enables multi-layer antenna constructions and improves the design flexibility of high-frequency circuit boards.

3. R-5410 reduces processing costs during circuit board manufacturing.

- *1: Panasonic’s conventional product (ultra-low transmission loss multi-layer circuit board materials, MEGTRON7 R-5785)

Suitable applications:

Millimeter-wave antenna circuit boards (e.g. automotive millimeter-wave radars, wireless communication base stations), high-speed transmission circuit boards

[Product Features]

1. With a lower transmission loss, R-5410 improves the efficiency of millimeter-wave antenna signals.

Leveraging Panasonic’s proprietary thermosetting resin design technology, this new material exhibits excellent dielectric properties and good adhesion strength with low-profile copper foils. This combination of properties delivers the industry’s lowest level transmission loss for thermosetting resin circuit boards thus reducing signal losses and improving the efficiency of millimeter-wave band antenna communications.

2. R-5410 improves antenna design flexibility by enabling high frequency multi-layer circuit boards constructions.

This prepreg is made from a proprietary low-loss thermosetting resin. R-5410 enables the lamination construction of multi-layer boards consisting of antenna layers, in addition to the insulation bonding use of an antenna layer with other layers (such as signal layers of high-frequency circuits). The new material increases the design flexibility of high-frequency circuit boards, achieving compact and high-density modules integrated with antennas and improving the efficiency of antenna performance. Copper-clad laminates like product number R-5515, which are core materials, included in this product family, are commercially available.

3. R-5410 reduces circuit board manufacturing costs.

Since this prepreg is a thermosetting resin material, it can be processed using existing standard circuit board manufacturing equipment. It requires no special chemical solutions or processes. This reduces processing costs during circuit board manufacturing.

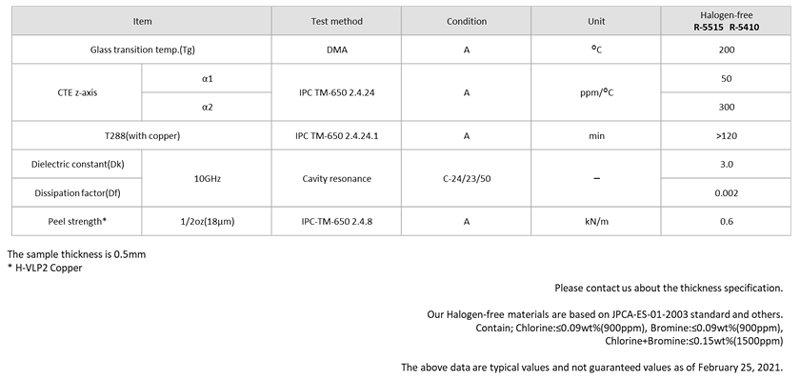

Basic specifications:

<Product no.> Core material: R-5515, Prepreg: R-5410

[Term Descriptions]

[1] Transmission loss

Extent to which signals that pass-through wires on printed circuit boards (transmission lines) attenuate in accordance with the material, distance, etc.

[2] Millimeter-wave band

Frequency range of 30-300 GHz

[3] Millimeter-wave radar

Sensor that detects the position/speed of an object by transmitting millimeter-wave band radio waves and receiving reflected waves from the object. Automotive millimeter-wave radar, which is mainly allocated at 76-81 GHz, is now more commonly mounted on vehicles as one of the sensors that constitute advanced driver-assistance systems (ADAS), a typical example of which is a collision prevention system.

[4] Beamforming technology

Technology that arranges multiple antenna elements and transmits highly directional radio waves in a specific direction from the phased array antenna that controls the phase of the arranged elements.

[5] Fluoropolymer circuit board materials

Printed circuit board materials whose insulators are made from a thermoplastic fluoropolymer (also referred to as PTFE, polytetrafluoroethylene, or fluorocarbon resin).

[6] Lamination manufacturing processes (Build-up method)

Method of forming a wiring layer consisting of multi-layers by laminating insulation layers (prepregs) and conductor layers (copper foils) layer by layer on a circuit board that serves as a core.

Media Contact:

Panasonic Corporation Brand Strategy Division Corporate PR Department

https://news.panasonic.com/global/contacts/

Inquiries:

Electronic Materials Business Division, Industrial Solutions Company

https://industrial.panasonic.com/cuif/ww/contact-us?field_contact_group=2343&field_contact_lineup=3249&ad=press20210225ww

Detailed product information:

5G Multi-layer PCB Solutions

https://industrial.panasonic.com/ww/electronic-materials/concept/5g_multi_pcb?ad=press20210225ww

About Panasonic

Panasonic Corporation is a worldwide leader in the development of diverse electronics technologies and solutions for customers in the consumer electronics, housing, automotive, and B2B businesses. The company, which celebrated its 100th anniversary in 2018, has expanded globally and now operates 528 subsidiaries and 72 associated companies worldwide, recording consolidated net sales of 7.49 trillion yen for the year ended March 31, 2020. Committed to pursuing new value through innovation across divisional lines, the company uses its technologies to create a better life and a better world for its customers. To learn more about Panasonic: https://www.panasonic.com/global.